ENVIROLYTE WATER DISINFECTING SYSTEMS

Envirolyte Water Disinfecting Systems are designed to disinfect:

- drinking water for municipalities and city residential areas

- water for brewing and beverage industries

- dairy factories and food production facilities

- water in swimming pools and for golf courses

- drinking water offshore for airports and shipping companies

- drinking water for restaurants, hotels, hospitals, schools etc.

|

|

HOW DOES IT WORK?

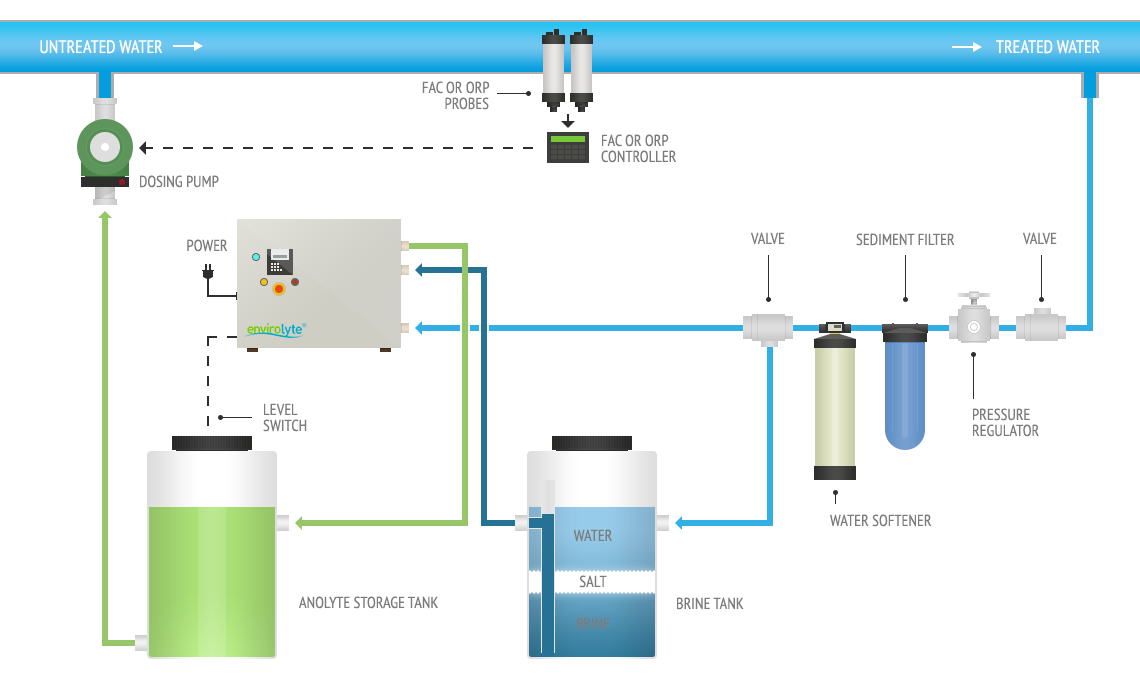

Every Envirolyte water disinfecting system consists of:

- Envirolyte unit (one or more)

- containers for Anolyte and NaCl solution

- dosing pump(s) with FAC or ORP controller

Anolyte produced by Envirolyte unit is collected in a container and then dosed into the incoming water (see above). The dosing regime depends on the water flow and quality (properties) of the source water and is controlled by either flow meter or FAC/ORP controller connected with dosing pump.

How is disinfecting achieved?

Aqueous solution of NaCl, electrochemically activated in Envirolyte unit, a powerful, non-toxic, non-hazardous disinfectant called Anolyte is the main disinfecting agent in any EWDS.

Anolyte is a colourless transparent liquid with a slight chlorine smell. It contains various mixed oxidants predominantly hypochlorous acid which give Anolyte highly bactericidal and sporicidal activity.

Anolyte parameters are as follows:

- pH from 2.0 to 8.5

- concentration (general) of active chlorine 100-6000 mg/l

- very high oxidant activity with low (hundreds parts of percentage) concentrations of working substances that don't harm chemical and other vital characteristics of the treated water and don't form any toxic compounds.

To find out how to monitor the parameters of Anolyte, please send your enquiry.. to the Envirolyte Industries International Ltd.

THE BENEFITS OF ENVIROLYTE WATER DISINFECTING SYSTEMS

- Due to very low concentration of active chlorine, Anolyte diluted in the water does not result in any toxicity effects neither forms any toxic by-products.

- Anolyte penetrates tiny pores of the water pipes or any other material.

- Anolyte eliminates biofilm and algae from the distribution system.

- Water pipes and equipment don't have to be rinsed with water after disinfecting.

- Anolyte doesn't harm the original, natural properties of the water.

- Anolyte eliminates chlorine taste and odour, improves taste and odour from algae.

- Anolyte can be stored and kept for further use when the necessity arises.

- Easy dosing.

- High level of safety: no hazardous chemicals produced or used.

PRODUCTS COMPARISON

|

Gas Chlorine |

Delivered Hypo |

Hypo Calcium |

Chloramination |

Chlorine Dioxide |

Anolyte |

|

|

Effective |

|

|

|

|

|

|

|

Safety |

|

|

|

|

|

|

|

Chlorine Residual |

|

|

|

|

|

|

|

TTHM / HAA5 Reduction |

|

|

|

|

|

|

|

Chlorine / Bromate Reduction |

|

|

|

|

|

|

|

Biofilm Removal |

|

|

|

|

|

|

|

Algae Elimination |

|

|

|

|

|

|

|

Micro Flocculation |

|

|

|

|

|

|

|

Eliminate T. & O. |

|

|

|

|

|

|

|

Easy to Maintain |

|

|

|

|

|

|

|

Lifecycle Costs Low |

|

|

|

|

|

|

WHY ENVIROLYTE WATER DISINFECTING TECHNOLOGY IS BETTER THAN TRADITIONAL CHLORINATION?

- Although seemingly analogous to chlorine, anolyte is unique and clearly superior to sodium hypochlorite in the destruction of spores, bacteria, viruses and other pathogen organisms on an equal residual base. Sodium hypochlorite in concentration of 5% is effective only in disinfection, but not sterilization. Sodium hypochlorite is neffective against cysts (Guardia, Cryptosporidium);

- Most of the pathogens, particularly water born, develop resistance to Sodium hypochlorite over time.Anolyte application, as water disinfectant on a daily basis for more than ten years, demonstrated that microorganisms do not develop resistance against anolyte over time;

- The required contact time for anolyte is lower;

- Sodium hypochlorite loses its activity during long-term storage and poses potential danger of gaseous chlorine emission during storage;

- Anolyte is better soluble;

- The bactericidal efficiency remains in pH values between 4 and 9;

- Anolyte is minimally corrosive primarily due it’s low concentrations and, also due, to the elimination of the caustic element normally found in Sodium and Calcium Hypochlorite;

- The reaction of anolyte and organic materials produces about half of the trihalomethanes as does chlorine;

- Anolyte eliminates existing scale and pathogens harbored in scale and blocks dissolved solids in supplied water from forming new scale. Biofilm is eliminated. Sections of a building are not required to be closed to normal use during treatment;

- Envirolyte Anolyte system does not involve hazardous chemicals or burdensome maintenance.

|

|

| Before dosing anolyte | After dosing anolyte |

For detailed operation procedure please send your enquiry..